WHERE WE COME FROM

Cosmetics laboratory for third-party manufacturing with more than 75 years of experience, positioned as one of the leading companies in the design and manufacture of facial cosmetics, body cosmetics and hair cosmetics.

WHERE WE COME FROM

Cosmetics laboratory for third-party manufacturing with more than 75 years of experience, positioned as one of the leading companies in the design and manufacture of facial cosmetics, body cosmetics and hair cosmetics.

Although our beginnings were focused on the manufacture of hair cosmetic products, thanks to our team, we have also introduced facial cosmetics and body cosmetics products to our portfolio.

Currently, we have achieved excellence as a laboratory for the manufacture of cosmetic products by complying with the strict quality control processes required to be a manufacturer of cosmetic products.

A team of R+D+i professionals works and is available daily for our customers in order to provide cutting-edge solutions that, together with the wide range of machines for the production of cosmetic products, positions us as a versatile laboratory, with the highest level of professionality and with high-quality standards.

Thanks to all of this, we can be proud to work for clients from more than 50 different countries. This is an added value, since it allows us to manufacture for third parties for any type of hair or skin at an international level.

ATEX ROOM REACTORS

In many of our production processes, also reproduced by many other companies in the industrial sector, there is a risk of explosions due to flammable particles that are in the environment during the manufacturing process, such as gases, vapours, mist or dust.

This type of explosion arises due to an exothermic combustion reaction (when an oxidizer reacts with a fuel, causing it to burn and therefore releasing energy in the form of light and heat) that ends in the immediate propagation of the flames in a few seconds and putting the safety of workers at risk.

To avoid these types of accidents, the Atex Rooms were created. At Hipertin we have an ATEX Room to guarantee the health and safety of our workers.

WHITE ROOM

At Hipertin we have a WHITE Room. It is a closed space that minimizes the amount of possible contaminants such as bacteria and/or particles in the air and on surfaces. Furthermore, using the white room, we can also control the temperature, humidity and air pressure.

White rooms require control of various environmental parameters such as: particles in the air, temperature and humidity of the environment, air flow and pressure…

Such comprehensive measurements are made thanks to an architectural control in the room, a facility with special room equipment.

To carry out this exhaustive control and to be able to respond to the specific needs of the activity that takes place within the space, the installation of the room requires a project that establishes a three-fold control: an architectural project, a facilities project and another one for the auxiliary equipment.

The White Room protects from all those contaminants (including the personnel who carry out the work inside the room) that could endanger the quality of the product that is handled during the manufacturing process.

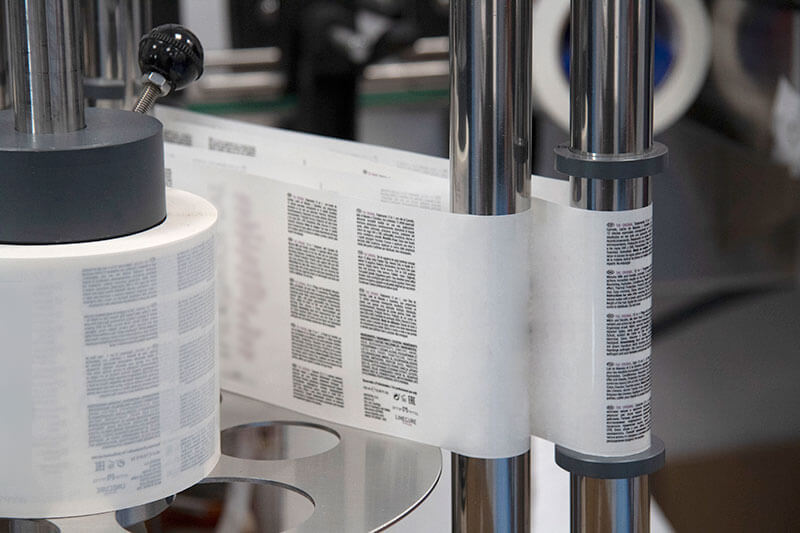

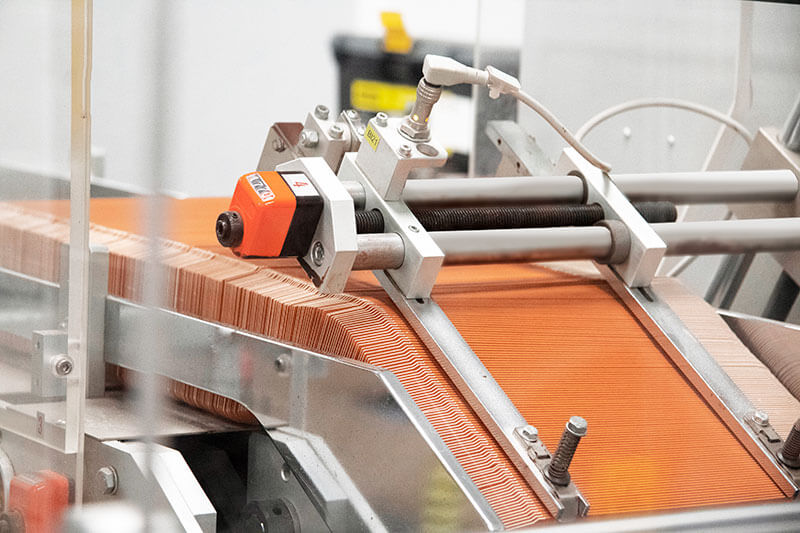

FACILITIES

State-of-the-art facilities, specific for the industrial production of hair cosmetics, facial cosmetics and body cosmetics.

PURPOSE

Our mission is to manufacture cosmetic products with the goal of adding value to your brand.

HUMAN TEAM

A sum of individual energies that multiplies to lend all our experience to our clients.